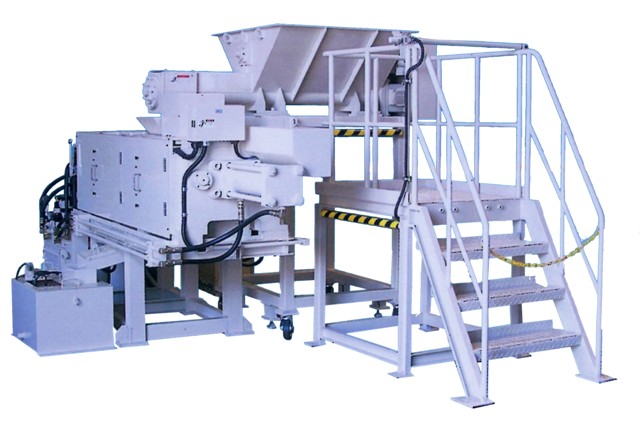

Environmental Machine【MKS・MSZ】

- Category:

- 2011/09/26

| Production table(kN) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Hoeing(MSZ) | 300 | |||||||||

| Suramel Z(MSZ) | 500 | 1000 | 1600 | 2000 | 3000 | 3500 | ||||

| Katamel α(MKS) | 1000 | 1600 | 2000 | 3000 | 3500 | |||||

| Katamel α【aluminum】(MKS) | 1200 | 2000 | 3000 | |||||||

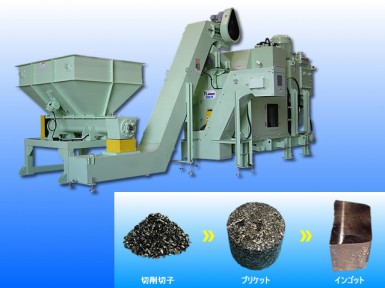

Future of Disposal plant grinding sludge

Casting briquettes were solidified Our machine, it will be the raw material as it is dissolved. Has been achieved, low-cost and non-polluting.

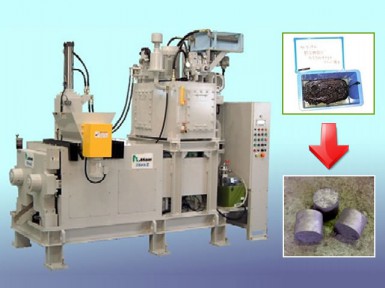

Disposal plant grinding sludge

(Supports Oil soluble & Water soluble in both.)

Future of Disposal plant grinding sludge

Abrasive sludge is difficult to briquette. After primary treatment of grinding sludge, paying the cost to go with industrial waste treatment company.

However, the use of our plant, made it possible to briquetting the sludge grinding, and removing the cutting fluid in the process.

And grinding sludge is briquetted, can be reused as raw material for melting.

Suramel MSZ-W 250ton

(Supports Oil soluble)

Suramel MSZ-S 100ton

(Supports Water soluble)

「Guidance of the sample test」

- Briquette test of Chip compacting machine and Disposal plant grinding sludge are possible.

- Briquette processing by our test facility. We will check the Fe content to dissolve the briquette.

For a sample test

- We will receive material from the customer, and then test it. Then we will consider the design of equipment.

If the steel chips

:Please send us your chips into the pails.

If the grinding sludge

:If it is primary treatment, please send into the pails.

If untreated, please send things that, precipitated a few days, accumulated at the bottom, into the pails.

Cost of customer:

- Round-trip transportation costs of materials and Briquette.

- Cost of test, such as X ray analysis. Cost such as travel expenses, if customers come to test.

Our side cost:Test cost of test machine (material (18 liter) pails up to 3 cans)

※If the amount of test material for more than 3 cans will the additional costs. (Separately arrangement)

Hydraulic Orbital Forging Press【MCOF】

- Category:

- 2011/09/26

| 【Main specifications of the Hydraulic orbital forging press.】 | ||||

|---|---|---|---|---|

| Form | MCOF-250 | MCOF-400 | MCOF-650 | |

| Output | (kN) | 2500 | 4000 | 6500 |

| Knockout Output | (kN) | 300 | 700 | 1300 |

| Pressing speed | (mm/s) | 3~30 | 3~25 | 3~25 |

| The number of orbital rotation | (rpm) | Max. 320 | Max. 300 | Max. 280 |

| Stroke Length | (mm) | 220 | 320 | 450 |

| Stroke adjustment amount | (mm) | 75mm below the upper limit | 40mm below the upper limit | 100mm below the upper limit |

| Knock-out stroke | (mm) | 65 | 100 | 115 |

| Diameter of the largest product | (mm) | 160 | 210 | 240 |

| Total power | (kW) | 89 | 220 | 265 |

| Hydraulic oil tank | (l) | 1000 | 1300 | 1500 |

Feature

- Orbital forging in order to pressure forming locally, can be formed by the power of 1/5 to 1/10 for the general press molding was carried out it upsetting.

Therefore, can significantly reduce the investment and basic facilities such as, Press, Tool, Foundation work.

- Less restraint of the tool and the material, processing range is greatly improved, can be molded precision parts, such as thin-walled.

- The orbital motion has four types of motion, can be formed in the shape of a variety of products to choose the motion.

- It is less noise and vibration compared to the general press. You can improve the working environment.

- Tool change time is short, it suitable for high-mix low-volume production.

- Registration function of the data processing is included. Processing conditions can be reproduced immediately that you have registered.

Therefore, can significantly reduce the investment and basic facilities such as, Press, Tool, Foundation work.

Plastic Forming Press【MSF】

- Category:

- 2011/09/26

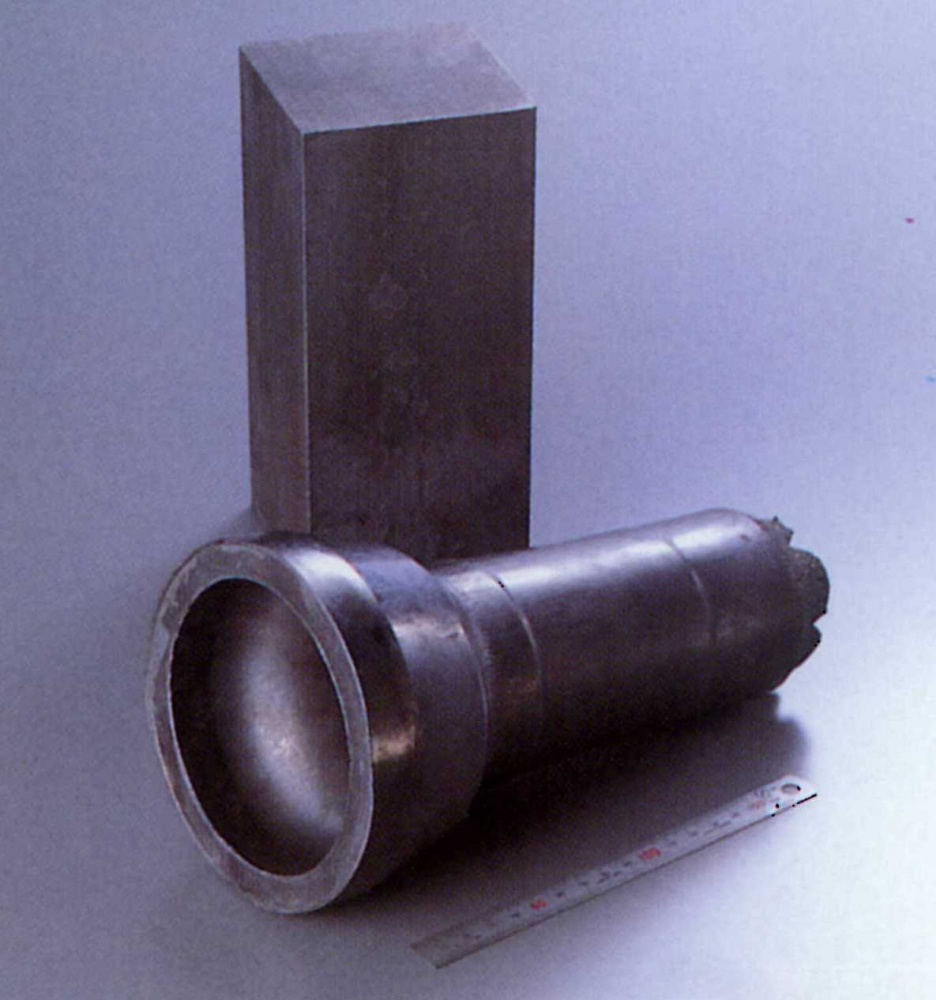

Samples

Feature

- In order to obtain accurate product efficiently in a Plastic forming (Thermoset, thermoplastic), our press, high accuracy, to maintain accuracy for eccentric load and thermal deformation.For this reason, the press body, the straight side frame is easy to maintain accuracy, has adopted the high-rigidity body structure to hold dynamic precision and accuracy for eccentric load.

- When the Plastic forming, it must be accurate starting position of the preload and pressure, it must be accurate speed of the preload and pressure, and requires that the excellent reproducibility of these actions.

Therefore, in our press, using a variable displacement pump, has been controlled by the hydraulic and electrical.

Therefore, in our press, using a variable displacement pump, has been controlled by the hydraulic and electrical.

Hydraulic Deep Drawing Press【MSF】

- Category:

- 2011/09/26

Samples

- Type of forging press

- MSF(Output tonnage)-(type of press)(Number of upper axis)(Number of bottom axis)

- Type of press M:Multi-axis more than 3-axis C:Cold forging O:Orbital forging H:Hot forging

Feature

- Hydraulic deep drawing is designed for the purpose of mass production of thin steel sheet drawing and blanking, for automobiles, electrical equipment, kitchen equipment, etc.

- Because this hydraulic press using a closed circuit, there is no shock at the time of switching.

- Press frame has a sufficient rigidity and strength to maintain high accuracy, is a straight-side frame.

- Place easy-to-use, push button, selector switch, instrument, valve adjustment, etc., will help driving safe and secure operations.

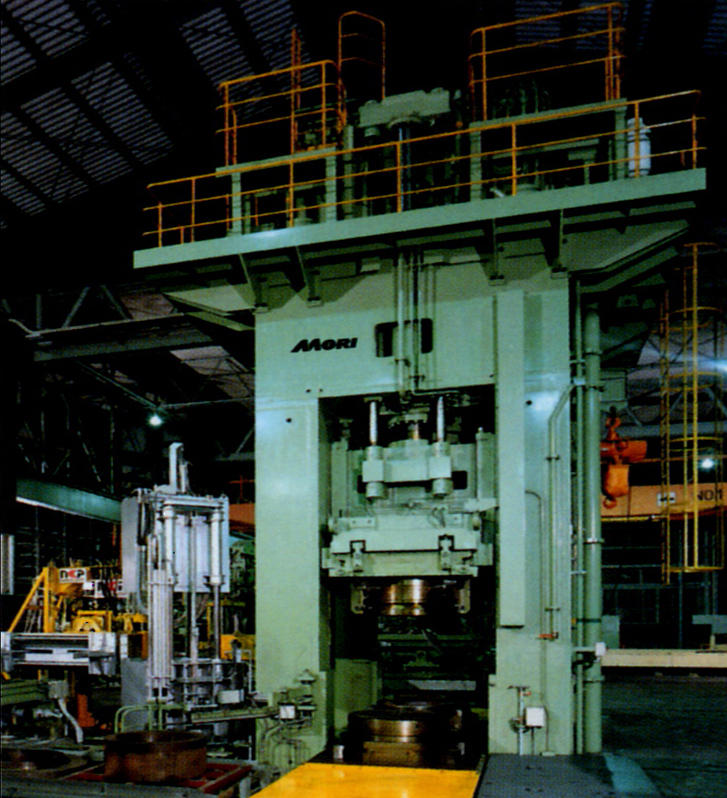

Hot Forging Press【MSF-H】

- Category:

- 2011/09/26

Samples

- Type of forging press

- MSF(Output tonnage)-(type of press)(Number of upper axis)(Number of bottom axis)

- Type of press M:Multi-axis more than 3-axis C:Cold forging O:Orbital forging H:Hot forging

Feature

- The structure of high rigidity

Bed, Crown, Upright is a steel plate welded structure, has been strongly tightened by tie rods.

Robust frame structure, the thickness of the product less the difference, accuracy is always stable.

- Wide range of allowable eccentric load

Pillar and Ram mounting section are designed for heavy-duty, allowable eccentric load has been widely taken.

- Excellent formability

You can set the arbitrary, force, speed, stroke, knockout power, position of each step. Therefore, rough finish finishing, Pierce, without burrs etc, can be formed at optimum conditions.

Closed die forging, Deep hole forging, Free forging, Rolling forging (Pre-processing), etc, we offer the best specification in each of the forming.

Bed, Crown, Upright is a steel plate welded structure, has been strongly tightened by tie rods.

Robust frame structure, the thickness of the product less the difference, accuracy is always stable.

Pillar and Ram mounting section are designed for heavy-duty, allowable eccentric load has been widely taken.

You can set the arbitrary, force, speed, stroke, knockout power, position of each step. Therefore, rough finish finishing, Pierce, without burrs etc, can be formed at optimum conditions.

Closed die forging, Deep hole forging, Free forging, Rolling forging (Pre-processing), etc, we offer the best specification in each of the forming.