Cold Closed Forging Press【MSF-C】

| 【Main specifications of the Cold closed forging press】 | ||||

|---|---|---|---|---|

| Type | MSF600 | MSF800 | MSF1000 | |

| Main | Ability(kN) | 650〜6,500 | 800〜8,000 | 1,000〜10,000 |

| Pressing speed(mm/s) | 20〜40 | 20〜40 | 20〜40 | |

| Stroke Length(mm) | Max. 300 | Max. 300 | Max. 300 | |

| Open height(mm) | 900 | 1,000 | 1,000 | |

| Slide area(mm) left and right×front and rear |

800×800 | 950×950 | 1,050×1,050 | |

| Bolster area(mm) left and right×front and rear |

800×900 | 950×1,100 | 1,050×1,200 | |

| Slide knockout | Ability(kN) | 150 | 200 | 300 |

| Knockout speed(mm/s) | 100 | 100 | 100 | |

| Stroke Length(mm) | 30 | 60 | 90 | |

| Bed | Ability(kN) | 400~4,000 | 500~5,000 | 1,000~9,500 |

| Pressing speed(mm/s) | 20〜40 | 20〜40 | 20〜40 | |

| Stroke Length(mm) | Max. 60 | Max. 70 | Max. 90 | |

| Bed knockout | Ability(kN) | 400 | 500 | 1,000 |

| Knockout speed(mm/s) | 50 | 50 | 50 | |

| Stroke Length(mm) | Max. 90 | Max. 90 | Max. 90 | |

| Total power(kW) | 220 | 340 | 340 | |

- Type of forging press.

- MSF(Output tonnage)-(Type of press)(Number of upper axis)(Number of bottom axis)

- Type of press M:Multi-axis more than 3-axis C:Cold forging O:Orbital forging H:Hot forging

Feature

- Improvement of materials stock utilization, reduction of post-processing.

The design of the optimal deformation process, that product accuracy improved, wasted Burr does not occur, to greatly improve the material stock utilization.

Then, complete the required minimum post-processing, reduce the number of steps, will lead to cost reductions.

- Energy saving

For the parts that need to pressure, from the appropriate direction and pressure to forming, forming load can be reduced.

- Environmental improvement of working space.

Compared with hot forging, no heating furnace, so less noise and vibration, improve the work space environment.

- Labor saving

For without the need skilled, forming is completed in one step, can be operated in a human operator.

The design of the optimal deformation process, that product accuracy improved, wasted Burr does not occur, to greatly improve the material stock utilization.

Then, complete the required minimum post-processing, reduce the number of steps, will lead to cost reductions.

For the parts that need to pressure, from the appropriate direction and pressure to forming, forming load can be reduced.

Compared with hot forging, no heating furnace, so less noise and vibration, improve the work space environment.

For without the need skilled, forming is completed in one step, can be operated in a human operator.

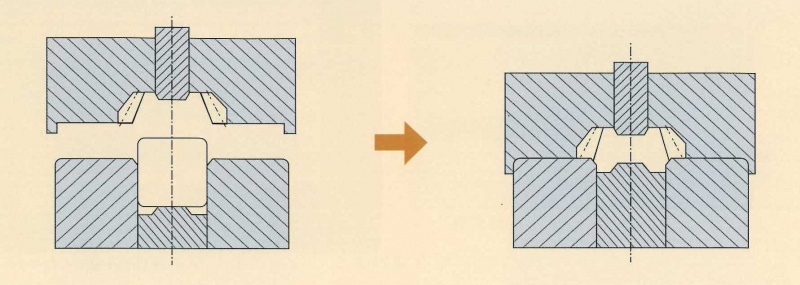

The principle of the method closed forging

- Closed forging method, material closed state in the mold, push the material in the mold by punch, material will be filled into a mold.